We make what moves you.

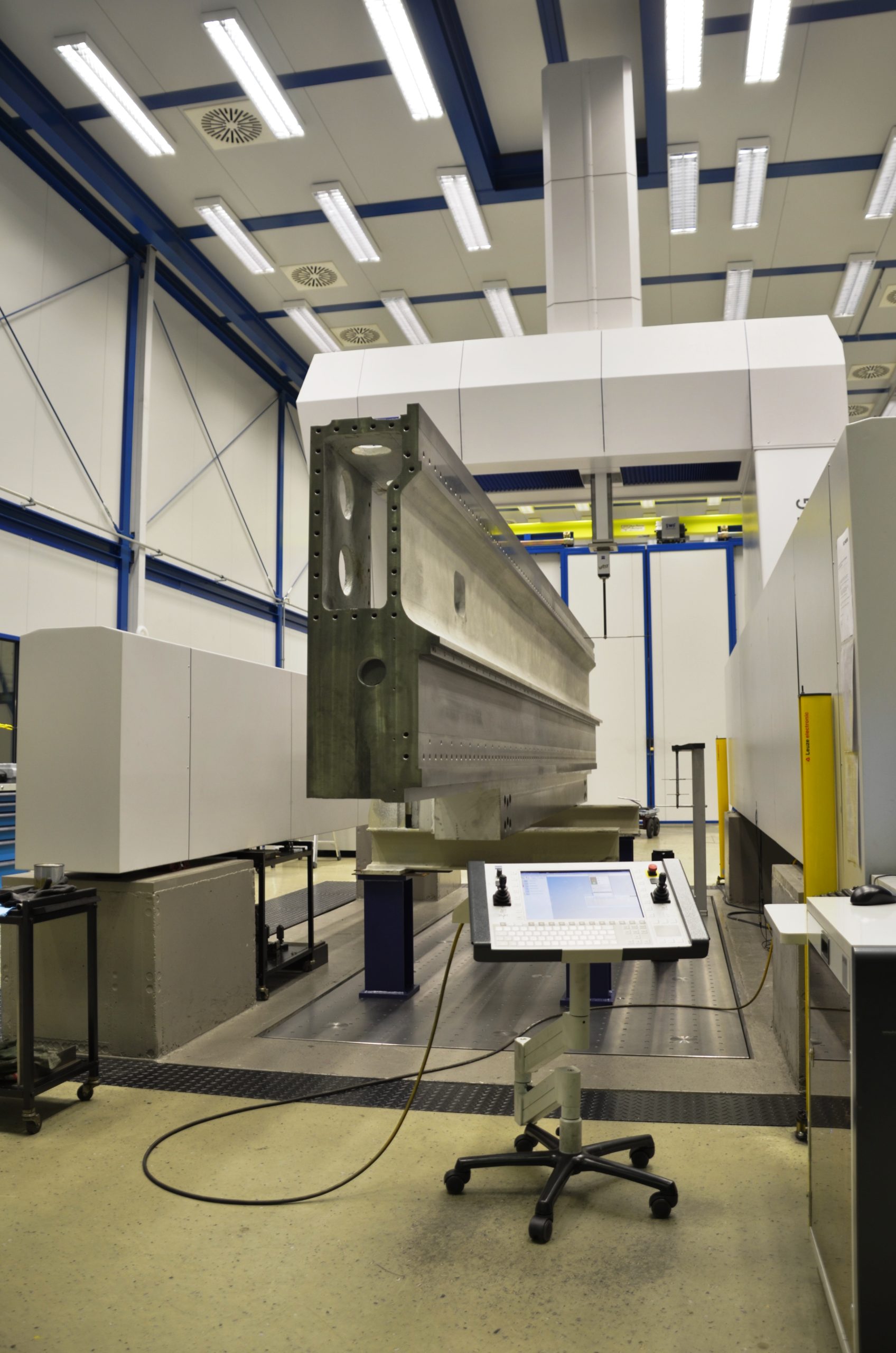

With state-of-the-art machinery and decades of experience, SCHIESS manufactures complex workpieces according to customer specifications – even in large dimensions and tight tolerances.

Contract manufacturing at the highest level – SCHIESS makes it possible.

Whether individual parts, small series or complex large components: In our contract manufacturing department, we combine decades of experience with state-of-the-art machine technology. Specialising in sophisticated machining and large-scale processing, we manufacture precisely according to customer specifications – efficiently, on time and with uncompromising quality control.

Our strengths lie in the machining of large, heavy and complex workpieces. We rely on an end-to-end structured process – from technical advice and CAM-supported work preparation through to precise final inspection. Every component that leaves our factory stands for the highest level of manufacturing expertise ‘Made in Germany’.

In addition to the possibilities of mechanical processing, we offer the option of horizontal balancing of components up to 3,000 mm long with a maximum weight of 700 kg.

You can rely on a partner who understands your requirements – and realises your components exactly to measure.

Our promise

Precision in the process. Quality in the result.

1. Technical enquiry & project analysis

Based on your technical drawings and requirements, we analyse feasibility, select suitable manufacturing processes and advise you on optimisation potential.

2. Offer phase

You receive a precise, transparently calculated offer with defined delivery times, clear performance specifications and customised solutions.

3. Work preparation & process planning

Our production specialists use state-of-the-art CAM systems to plan the optimum production process – taking deadlines, resources and quality assurance into account.

4. CNC machining & manufacturing

Machining is carried out on high-precision machine tools in compliance with the tightest tolerances – even for large components with complex geometries.

5. Quality assurance

At every stage of production, we ensure compliance with your specifications through structured testing processes, documented measurement protocols and modern measurement technology.

6. Delivery & project completion

After a successful final inspection, the product is delivered on time. On request, we can also assist you with follow-up projects, series production or additional services.

Technical support & project enquiry

Your direct contact for contract manufacturing:

Head of contract manufacturing

Mr. Liebich

☎ +49 3473 968 – 160

Deputy Head of Contract Manufacturing

Mr. Richter

☎ +49 3473 968 – 161

Quality assurance – excellence at every step

Quality is our top priority. Our customers rely on our precision, which is evident not only in production, but also in quality assurance. From the first stage of production to the final delivery, we ensure that every component meets the highest standards.

Our quality assurance processes

1. Precise measurement technology:

We use the latest measuring technologies, such as coordinate measuring machines (ZEISS -CMM) and 3D measuring systems, to check every workpiece with high precision. Even complex geometries and tight tolerances are no problem for us. All measurements are carried out in our air-conditioned measuring room (reference temperature 20° C).

2. Process monitoring:

Throughout production, we continuously monitor all relevant process parameters – from tool life to temperature and stress values – to ensure maximum precision and repeatability.

3. Documented tests:

Every step is carefully documented so that all tests are traceable and transparent. On request, we can provide you with test reports and measurement protocols that enable complete traceability.

4. Final inspection:

Before delivery, we subject every product to a final inspection in which all specific requirements and quality standards are checked. Only fully tested and certified products leave our factory.

5. Certificates and standards:

We work in accordance with internationally recognised quality standards such as ISO 9001 and other relevant standards. Our quality assurance is always up to date in order to fulfil the highest industry requirements.

External orders in quality assurance – trust our expertise.

In addition to the quality assurance of our own production, we also offer external orders to check your products for the highest precision and quality. With our many years of experience and state-of-the-art measuring technology, we ensure that every component meets the highest industry standards.

Our quality assurance department offers you a comprehensive service that covers almost all relevant inspection and test procedures – from incoming inspection to final testing. You benefit from our certified processes, state-of-the-art measuring and testing technology and a qualified team that realises your requirements with the utmost care.

Our services for external orders:

-

Testing and measurement of components for tolerances, material properties and surface quality

-

Final inspections and creation of test reports for complete traceability

- Customised testing requirements that are precisely tailored to your needs

Why choose us?

-

State-of-the-art measurement technology: We use the latest technologies and equipment to ensure precise and reliable quality assurance.

-

Transparency and traceability: All inspection processes are documented and can be traced at any time.

-

Experienced specialists: Our qualified team has many years of experience in the quality inspection of components from a wide range of industries.

Our measurement technology

ZEISS 3D coordinate measuring machine MMZ-G with rotary table for gear measurements : measuring volume 5000x2000x2800. The machine is equipped with the Zeiss Calypso and Gear Pro Involute measuring software. This enables all standard geometries and cylindrical gears to be measured and analysed.

3D laser tracker from Leica, measuring radius with reflector 90 m, with T-Probe 15 m. The measuring device is mobile and can be used anywhere. It can be used to measure very large components on the spot; the ZEISS Calypso measuring software is also used here.

Renishaw XL 80 laser interferometer: Measuring range 80 m.

Renishaw XR 20 rotation angle measuring device: Unlimited rotation angle (for rotary axes).

The Renishaw laser measuring system is used for checking and compensating the positioning accuracy of linear and rotary axes on machine tools. In addition, straightness measurements, e.g. of guideways on machine beds, can be carried out up to a length of 80 metres.

All employees working on these machines are qualified in accordance with AUKOM 2. Regular training courses, e.g. form and position, guarantee continuous further development.

Precision starts here – your contact for quality assurance.

Your direct contact for quality assurance:

Mr. Gutmann

☎ +49 3473 968 – 321

Mr. Umlauf

☎ +49 3473 968 – 198