MILLING MACHINES

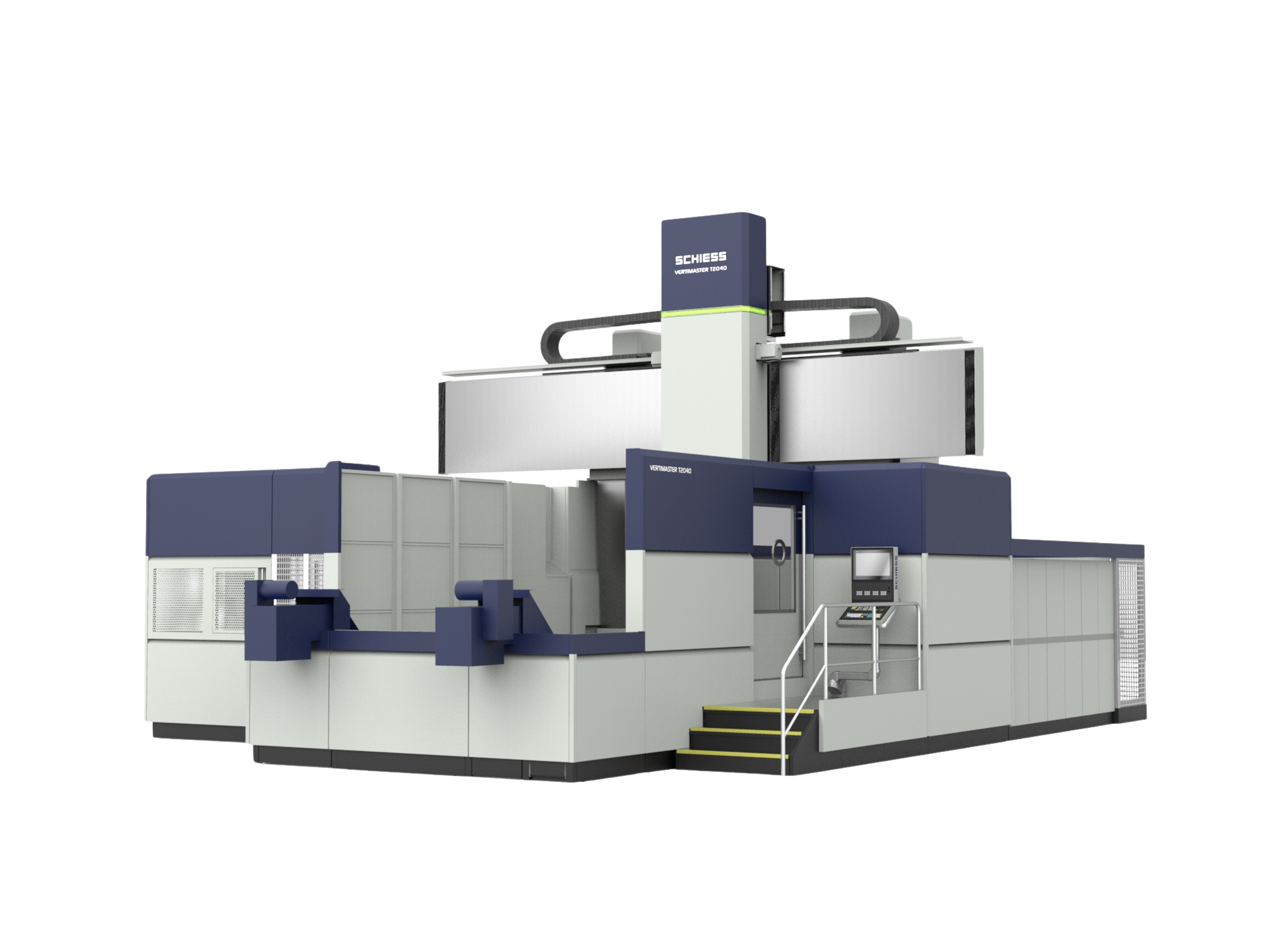

VERTIMASTER VMG

The largest machine in its class. Superior performance, maximum precision.

Gantry-type portal milling machine with 4 axes (X, Y, Z, C)

The VERTIMASTER VMG, as a gantry-type portal milling machine with 4 axes, is one of the most modern XXL multitasking machines of its kind with its design features. This machine concept guarantees the user maximum productivity and flexibility with fast throughput times at low cost. The VERTIMASTER is designed to fulfil individual customer requirements in every respect through a combination of modular components. The X travel in particular can be customised – travels of over 50,000 mm were no limit for us.

Modular design for optimum adaptation to all machining tasks

Frame assemblies made of high-quality cast iron with excellent vibration damping properties

CNC control with Sinumerik One

Precise, durable, wear-free, hydrostatic guides

Highest drive power and maximum torques

RAM'S with Masterhead principle

| VERTIMASTER VMG | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|

| Width of plate field / table, max. t1 in mm | 3,000 | 4,000 | 5,000 | 6,000 | 7,000 | 8,000 | 9,000 | 10,000 | 12,000 |

| Drive power drilling & milling drive in kW | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 |

| Processing height max. h in mm | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 |

Each machine can be customised in the machine configurator.

Customise nowVERTIMASTER VMT

Portal milling machine in table design with up to 4 axes (X, Y, Z, C) in single, double or coupled table design

With its design features, the VERTIMASTER VMT is one of the most modern XXL multitasking machines of its kind. This machine concept guarantees the user maximum productivity and flexibility with fast throughput times at low cost. The VERTIMASTER is designed to fulfil individual customer requirements in every respect through a combination of modular components.

Modular design for optimum adaptation to all machining tasks

Frame assemblies made of high-quality cast iron with excellent vibration damping properties

CNC control with Sinumerik One

Precise, durable, wear-free, hydrostatic guides

Highest drive power and maximum torques

RAM'S with Masterhead principle

Technology-orientated and flexible for all customer requirements

| VERTIMASTER VMT | 3 | 4 |

|---|---|---|

| Table width, max. t1 in mm | 3,000 | 4,000 |

| Drilling & milling drive power in kW | 52 / 72 | 52 / 72 |

| Processing height, max. h in mm | 3,000 | 5,000 |

Each machine can be individually customised in the machine configurator.

Customise nowVERTIMASTER t - serie

Performance, precision, ease of operation and, last but not least, ease of servicing characterise this new generation of portal milling machines in table design. The machine bed, table, column, connecting part and cross beam are made of high-quality cast iron. The cross beam is infinitely adjustable. A gearless direct drive with a high nominal speed (550 rpm) is used for the milling drive, a highlight of the machine. The proven MASTERHEAD interface has been extended for 2-axis NC heads with motor spindles to cover applications in the aerospace sector as well as mould and tool making. The new development of the table is based on bionic findings and is designed with a special honeycomb structure. It is therefore particularly dimensionally stable and yet weight-optimised.

Modular design principle

Gearless drilling and milling drive with torque motor

All axes are centrally lubricated linear guide systems

MASTERHEAD principle - flexible up to 5-axis simultaneous machining

The latest, energy-efficient servo drives

Direct, absolute measuring systems in all axes for maximum accuracy

CNC control by Sinumerik 840D sl or Heidenhain iTCN530

| VERTIMASTER T | T 2040 | T 2060 | T 2560 | T 2580 | T 3060 | T 3080 |

|---|---|---|---|---|---|---|

| Table dimensions, W x L mm | 2,000 x 4,000 | 2,000 x 6,000 | 2,500 x 6,000 | 2,500 x 8,000 | 3,000 x 6,000 | 3,000 x 8,000 |

| Table load, max. t | 20 / 25 | 25 / 30 | 30 / 40 | 30 / 40 | 30 / 40 | 30 / 40 |

| Passage height mm | 2,000 / 2,500 | 2,000 / 2,500 | 2,500 / 3,000 | 2.500 / 3,000 | 2,500 / 3,000 | 2,500 / 3,000 |

| Travel path Z-axis (optional) mm | 1,100 (1,500) | 1,100 (1,500) | 1,100 (1,500) | 1,100 (1,500) | 1,100 (1,500) | 1,100 (1,500) |

| Spindle speed (optional), max. min⁻¹ | 4,000 (6,000) | 4,000 (6,000) | 4,000 (6,000) | 4,000 (6,000) | 4,000 (6,000) | 4,000 (6,000) |

| Torque, max. Nm | 1,000 | 1,000 | 1,000 | 1,000 | 1,000 | 1,000 |

Each machine can be individually customised in the machine configurator.

Customise now

VERTIMASTER high-speed series

VERTIMASTER aero

Aircraft construction today places very special demands on its processing machines, especially in the areas of dynamics and metal removal rates. The SCHIESS VertiMaster AERO portal milling machines consist of a modular machine concept that can be combined in different working areas, with different milling heads and control types, thus offering the best concept for machining workpieces for aircraft construction in almost all sizes and a wide variety of materials. The fixed table ensures that the workpiece weight has no negative impact on the dynamics of the machine.

High-gantry design for maximum precision and dynamics up to 5 m/s² in all linear axes; rack and pinion drives in all linear axes

Simple installation on a stable, level surface

Modular design for optimum adaptation to all machining tasks; machine beds in lengths of 3,000 mm, 4,000 mm and 5,000 mm for modular expansion of the machine

Highly dynamic A/C axle heads with direct drive technology

Controls, either SIEMENS 840 Dsl or HEIDENHAIN iTNC 640

| VERTIMASTER | AERO25 |

|---|---|

| Plate field width in mm | from 2,500 |

| Plate field length in mm | from 6,000 |

| Rapid traverse in mm/min | up to 45,000 |

Each machine can be individually customised in the machine configurator.

Customise nowVERTIMASTER VMG -x

These AERO CNC portal milling machines consist of a modular machine concept

machine concept that can be combined in different work areas, with different milling heads and control types, thus offering the best concept for machining workpieces for aircraft construction in almost all sizes and a wide variety of materials. The fixed table ensures that the workpiece weight has no negative impact on the dynamics of the machine.

High-gantry design for maximum precision and dynamics up to 5 m/s² in all linear axes; rack and pinion drives in all linear axes

Simple installation on a stable, level surface

Modular design for optimum adaptation to all machining tasks; machine beds in lengths of 3,000 mm, 4,000 mm and 5,000 mm for modular expansion of the machine

Highly dynamic A/C axle heads with direct drive technology

Controls, either SIEMENS 840 Dsl or HEIDENHAIN iTNC 640

| VERTIMASTER | VMG – X | |||||

|---|---|---|---|---|---|---|

| Plate field width in mm | from 2,500 | |||||

| Plate field length in mm | from 6,000 | |||||

| Rapid traverse in mm/min | up to 45,000 |

Each machine can be individually customised in the machine configurator.

Customise nowMilling / turning machines

VERTIMASTER VMG - PS

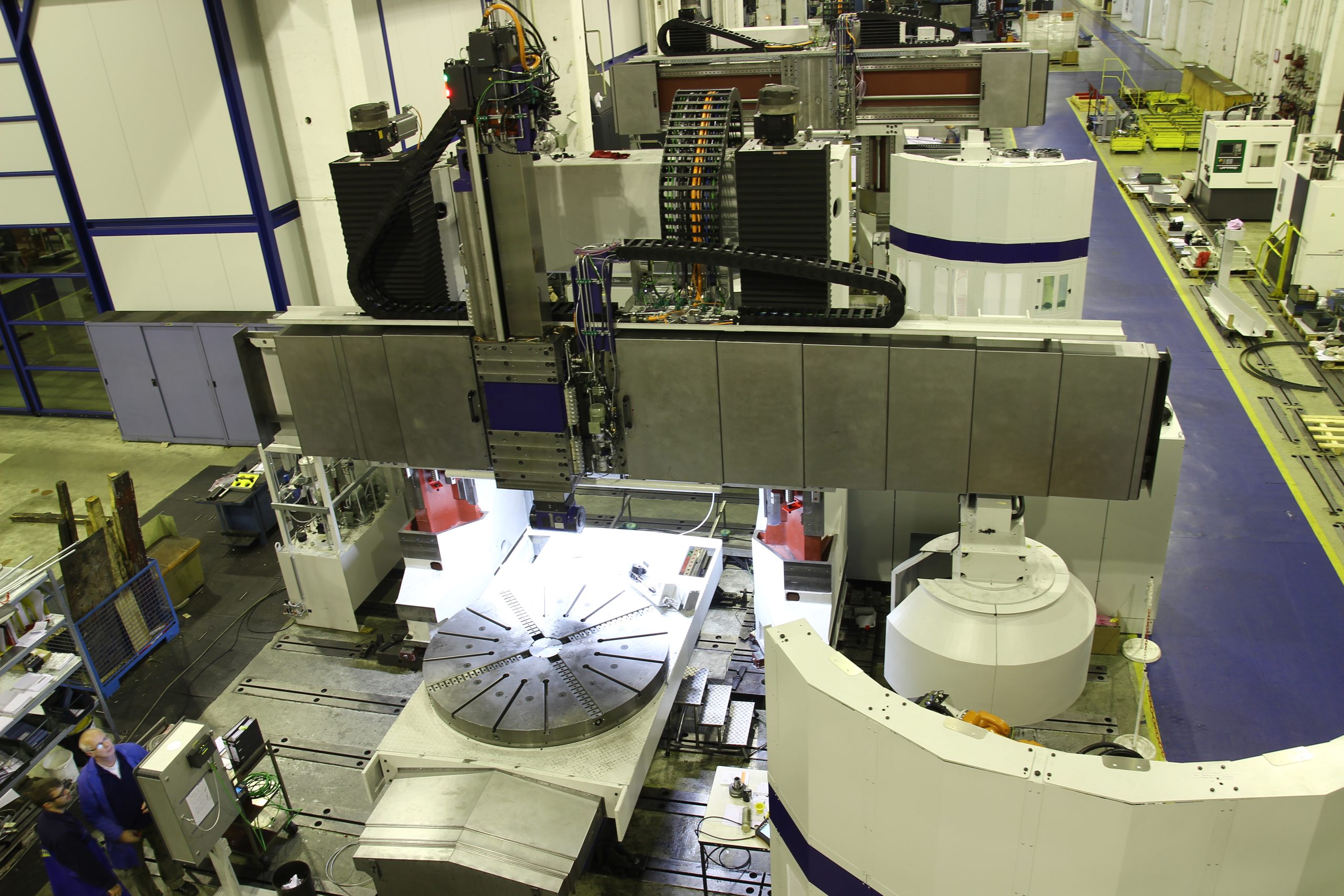

Gantry-type portal milling machine with 4 axes (X, Y, Z, C), with face plate

These XXL multitasking machines save time, space and costs by turning, drilling,

milling, grinding and other machining processes in a single set-up – for workpieces up to

for workpieces weighing up to 600 tonnes. These gantry-type turning/milling centres are among the most modern and largest machine tools in the world.

Gantry-type portal milling machine with 4 axes and face plate

Modular design

High-quality casting with maximum rigidity and vibration damping

Bending and torsion-resistant design due to force flow

Double pinion rack as drive element (electrically tensioned for maximum accuracy)

Hydrostatic axial bearing (face plate)

High payload (face plate)

Service- und wartungsfreundlicher Direktantrieb (Planscheibe, kein Schaltgetriebe)

Wear-free and extremely rigid guide

Double pinion rack as drive element (support carriage, electrically tensioned for maximum accuracy)

| VERTIMASTER VMG – PS | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|

| Diameter of faceplate in mm | 3,000 | 4,000 | 5,000 | 6,000 | 7,000 | 8,000 | 9,000 | 10,000 | 12,000 |

| Drive power drilling & milling in kW | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 | 52–100 |

| Drive power faceplate in kW | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Maximum processing height in mm | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 |

Each machine can be individually customised in the machine configurator.

Customise now

Turning machines

VERTIMASTER VT

Vertical lathe with 2 axes (X, Z)

These XXL multitasking machines save time, space and costs by turning, drilling,

milling, grinding and other machining processes in a single set-up – for workpieces up to

for workpieces up to 600 tonnes.

State-of-the-art, energy-efficient servo drives

Modular design principle

MASTER HEAD principle - flexible up to 5-axis simultaneous machining

All axes are centrally lubricated linear guide systems

Gearless drilling and milling drive with torque motor

Direct, absolute measuring systems in all axes for maximum accuracy

CNC control by Sinumerik 840D sl or Heidenhain iTCN530

| VERTIMASTER VT | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|

| Maximum table width in mm | 3,000 | 4,000 | 5,000 | 6,000 | 7,000 | 8,000 | 9,000 | 10,000 | 12,000 |

| Maximum processing height in mm | 10,000 | ||||||||

| Travel range X-/Y-axis in mm | application-specific | ||||||||

| Maximum faceplate load in t | 600 | ||||||||

Each machine can be individually customised in the machine configurator.

Customise nowTurning / milling machines

VERTIMASTER VM

Vertical lathe with 3 axes (X, Y, C), as well as drilling and milling drive

These XXL multitasking machines save time, space and costs by turning, drilling,

milling, grinding and other machining processes in a single set-up – for workpieces weighing up to

for workpieces weighing up to 600 tonnes and customised travels of over 50,000 mm. This machine concept guarantees the user maximum productivity and flexibility with fast throughput times at low cost. The VertiMaster is designed to fulfil individual customer requirements in every respect

to fulfil individual customer requirements in every respect through a combination of modular components.

Modular design for optimum adaptation to all machining tasks

Frame assemblies made of high-quality cast iron with excellent vibration damping properties

Wear-free, hydrostatic guideways for long-term precision

RAMs with masterhead principle, technology-orientated and flexible for all customer requirements

Highest drive power and maximum torques

| VERTIMASTER VM | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|

| Breite Plattenfeld / Tisch, max. mm | 3.000 | 4.000 | 5.000 | 6.000 | 7.000 | 8.000 | 9.000 | 10.000 | 12.000 |

| Bearbeitungshöhe, max. mm | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 |

| Verfahrweg X-/Y-Achse mm | anwendungsspezifisch | anwendungsspezifisch | anwendungsspezifisch | anwendungsspezifisch | anwendungsspezifisch | anwendungsspezifisch | anwendungsspezifisch | anwendungsspezifisch | anwendungsspezifisch |

| Belastung Planscheibe, max. t | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

Each machine can be individually customised in the machine configurator.

Customise nowVERTIMASTER v - serie

The VERTIMASTER V powerfully combines the machining processes of turning, drilling and milling in a single set-up, thus saving time and ensuring precise, effective machining of workpieces up to a diameter of 3 metres and a weight of 20 tonnes. In combination with an automatic head and tool change, the VERTIMASTER V can be quickly adapted to different production requirements.

No special foundation required

Automatic head and tool change

MASTERHEAD principle

Traversing faceplate (Y-axis), optional

Direct measurement systems

Easy to programme with Sinumerik 840D sl

Safety Integrated for turning and milling mode

| VERTIMASTER V | V12 | V16 | V20 | V25 |

|---|---|---|---|---|

| Construction type | Single-column design | Single-column design | Double-column design | Double-column design |

| Processing diameter mm | 1,600 | 2,000 | 2,500 | 3,000 |

| Passage width mm | – | – | 2,700 | 3,200 |

| Maximum workpiece height mm | 1,200 | 1,300 | 2,000 / 2,500 | 2,000 / 2,500 |

| Maximum workpiece weight kg | 8,000 | 12,000 | 16,000 | 20,000 |

| Travel range Z-axis mm | 1,400 | 1,400 | 1,400 / 1,600 | 1,400 / 1,600 |

| Travel range W-axis mm | – | 700 | 1,200 / 1,700 | 1,200 / 1,700 |

| Travel range X-axis (-/+) mm | 650 / 1,550 | 850 / 1,450 | 1,300 / 1,750 / 2,550 | 1,550 / 1,950 / 2,750 |

| Travel range Y-axis (-/+) mm | – | – | 1,000 / 1,000 | 1,250 / 1,250 |

| *Drilling & milling drive (optional): 46 kW; 3,500 min⁻¹; 1,200 Nm | ||||

Each machine can be individually customised in the machine configurator.

Customise now

Boring machines

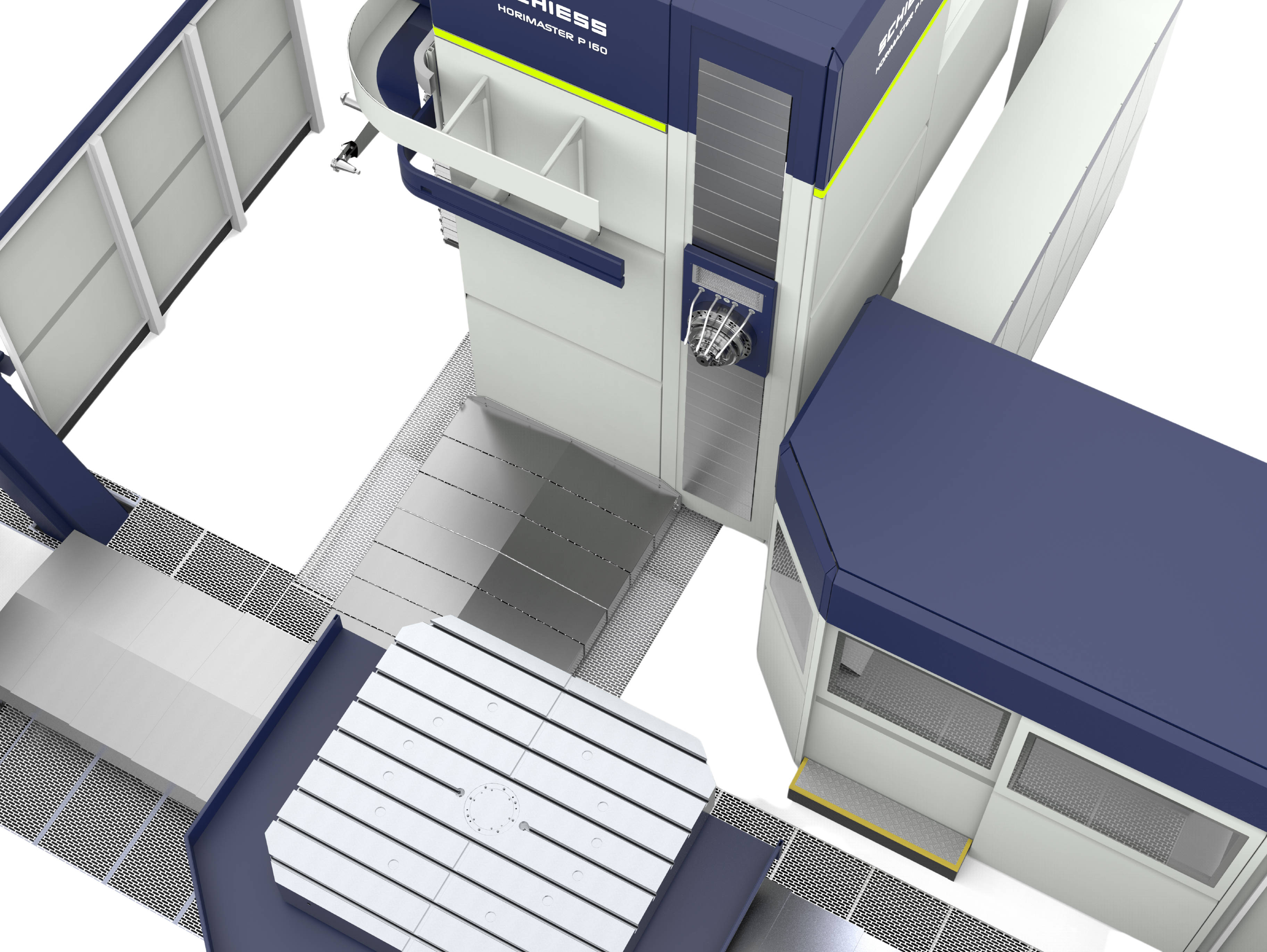

HORIMASTER p - serie

With the HORIMASTER P boring mill series, SCHIESS is building on its many years of success as a manufacturer of high-performance, high-precision boring mills. The modular HoriMaster P series offers every user an attractive price/performance ratio for a wide range of applications.

Whether powerful heavy-duty machining or the most precise finish machining: the HORIMASTER P is always a good and reliable choice.

Flexible adaptation to specific production tasks thanks to modular design principle

Dynamic positioning and low operating costs thanks to energy-efficient servo drives

Maximum stability and long-term accuracy

Absolute precision and repeat accuracy thanks to direct position measuring systems

| HORIMASTER | P130 | P160 | ||||

|---|---|---|---|---|---|---|

| Spindle diameter in mm | 130 | 160 | ||||

| Power in kW | 41 | 46 | ||||

| Torque in Nm | 2,500 | 3,000 | ||||

| Speed in min⁻¹ | 3,500 | 3,000 |

Each machine can be individually customised in the machine configurator.

Customise now