Milling Machines

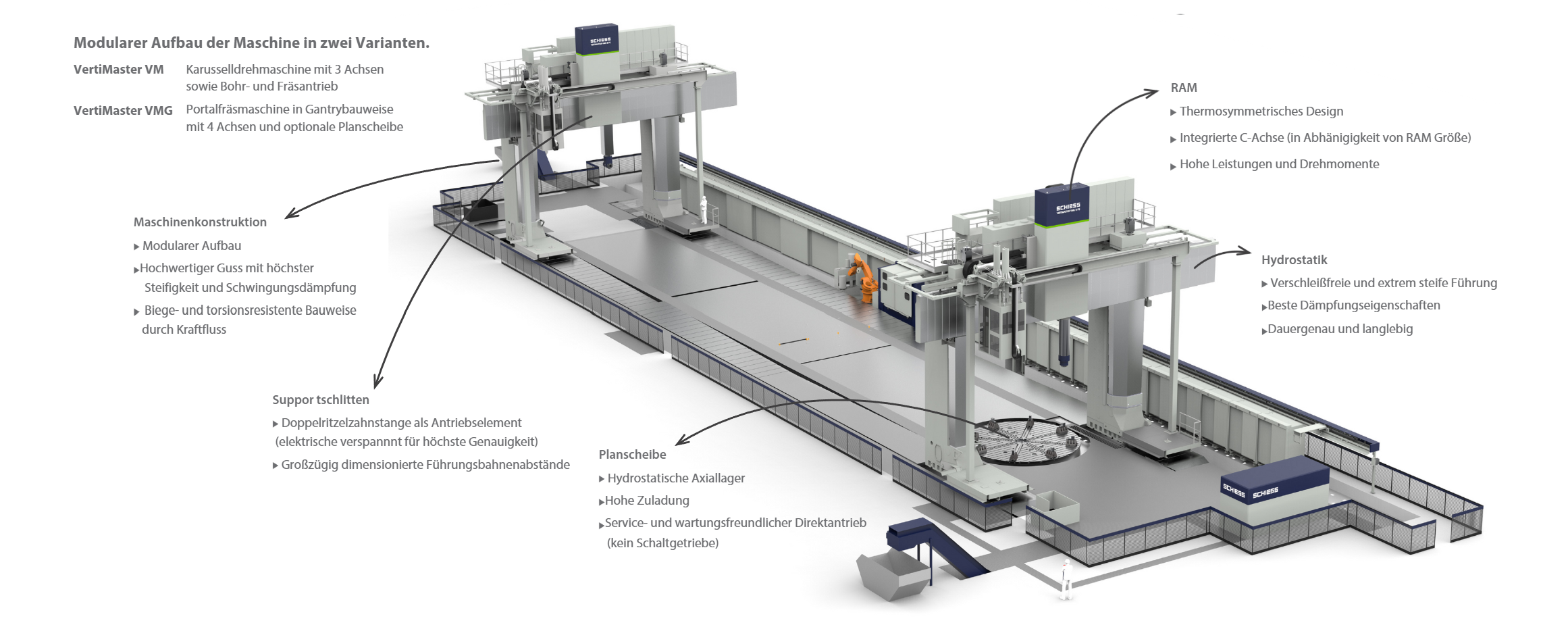

VERTIMASTER VMG

4-Axis Gantry-style Portal Milling Machine (X, Y, Z, C)

The VERTIMASTER VMG is a 4-axis gantry-style portal milling machine and one of the most advanced XXL multitasking machines of its kind, thanks to its innovative design features. This machine concept guarantees users maximum productivity and flexibility, with fast throughput times and low operating costs. The VERTIMASTER is engineered to meet individual customer requirements in every aspect through a combination of modular components.

| RAM Dimensions | mm | 280 x 240 | 420 x 340 | 520 x 460 | 640 x 570 / Ø560 |

|---|---|---|---|---|---|

| Drive Power (S1/100%), max | kW | 52 | 52 | 72 | 100 |

| Torque, max. | Nm | 2.400 | 2.400 | 6.000 | 9.000 |

| Speed, max. | rpm | 3.150 | 3.150 | 3.000 | 2.500 |

| RAM (Z-Axis) Extension, max. | mm | 1.800 | 2.600 | 3.000 | 4.000 |

| Integrated C-Axis | - | - | yes | yes |

| VMG | Unit | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Width of plate field, max. | mm | 2,000 | 3,000 | 4,000 | 5,000 | 6,000 | 7,000 | 8,000 | 9,000 | 10,000 |

| Processing height*, max. | mm | 3,000 | 3,000 | 5,000 | 7,000 | 7,000 | 7,000 | 7,000 | 7,000 | 7,000 |

| Travel path X-/Y-axis | mm | application-specific | ||||||||

*All the above technical parameters are individually adaptable; special dimensions available on request.

Every machine can be customized using our Machine Configurator.

Configure nowVERTIMASTER VMT

Portal Milling Machine in Table Design with up to 4 Axes (X, Y, Z, C), in Single, Double or Coupled Table Design

The VERTIMASTER VMT is one of the most advanced XXL multitasking machines of its kind, featuring cutting-edge design characteristics. This machine concept ensures maximum productivity and flexibility, delivering rapid throughput times with low operational costs. The VERTIMASTER is engineered to meet every customer’s unique requirements through a combination of modular components.

| VMT | Unit | 3 | 4 |

|---|---|---|---|

| Table Width | mm | 3.000 | 4.000 |

| Processing Height | mm | 3.000 | 5.000 |

| Travel Distance X-/Y-Axis | mm | application-specific | application-specific |

Every machine can be customized using our Machine Configurator.

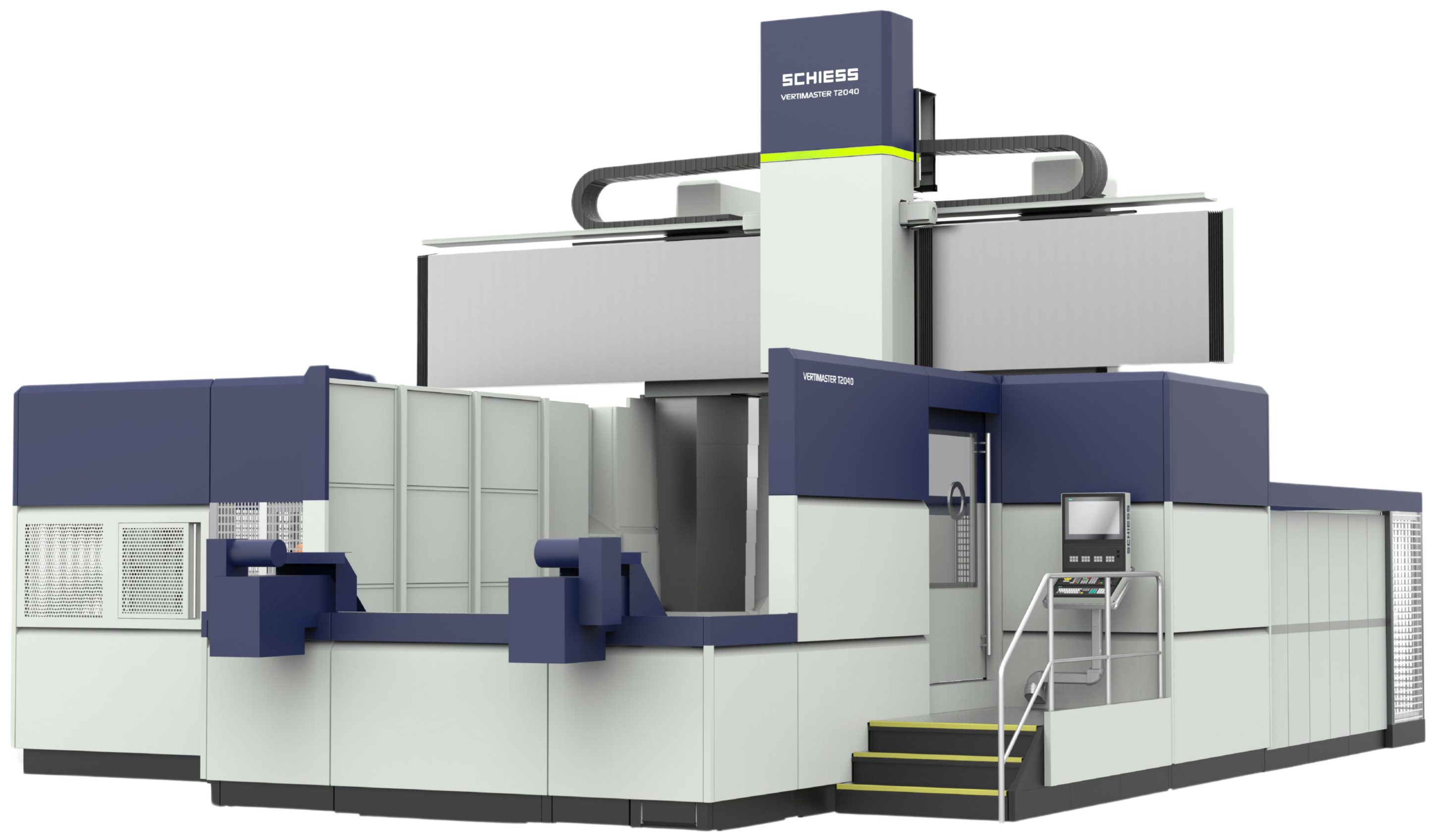

Configure NowVERTIMASTER T-SERIES

Gantry milling machine in table design with up to 4 axes (X, Y, Z, C) in compact dimensions

Performance, precision, user-friendliness, and serviceability define this new generation of table-style portal milling machines. The machine base, table, column, connecting components, and crossbeam are constructed from high-quality cast iron. The crossbeam features infinitely adjustable positioning. The milling drive — a standout feature of this machine — utilizes a gearless direct drive with high rated speed (550 rpm). The proven MASTERHEAD interface has been enhanced for 2-axis NC heads with motorized spindles, enabling advanced applications in aerospace, mold, and tool manufacturing. The newly developed table incorporates bionic design principles with a specialized honeycomb structure, achieving exceptional dimensional stability while remaining weight-optimized

| VERTIMASTER T-Series | T 2040 T 2060 |

T 2560 T 2580 |

T 3060 T 3080 |

|

|---|---|---|---|---|

| Table Dimensions (WxL) | mm | 2.000 × 4.000 2.000 × 6.000 |

2.500 × 5.000 2.500 × 6.000 |

3.000 × 6.000 3.000 × 8.000 |

| Table Load, max. | t | 20 / 25 | 25 / 30 | 30 / 40 |

| Clearance Height | mm | 2.000 / 2.500 | 2.000 / 2.500 | 2.000 / 2.500 |

| Travel Distance Z-Axis (optional) | mm | 1.100 (1.500) | 1.100 (1.500) | 1.100 (1.500) |

| Spindle Speed (optional), max. | rpm | 4.000 (6.000) | 4.000 (6.000) | 4.000 (6.000) |

| Torque, max. | Nm | 1.000 | 1.000 | 1.000 |

Every machine can be customized using our Machine Configurator.

Configure NowMilling / Turning Machines

VERTIMASTER VMG - PS

Portal Milling Machine in Gantry Design with 4 Axes (X, Y, Z, C), with Faceplate

These XXL multitasking machines save time, space, and costs by combining turning, drilling, milling, grinding, and other processes in a single setup – handling workpieces up to 600 tons. As gantry-style portal turning/milling centers, they rank among the most advanced and largest machine tools in the world.

| VMG-PS | Unit | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Diameter Faceplate, max. | mm | 2.000 | 3.000 | 4.000 | 5.000 | 6.000 | 7.000 | 8.000 | 9.000 | 10.000 |

| Processing Height*, max. | mm | 3.000 | 3.000 | 5.000 | 7.000 | |||||

| Travel Distance X-/Y-Axis | mm | application-specific | ||||||||

| Faceplate Load, max. | t | 400 | ||||||||

All the above technical parameters can be customized; special dimensions on request.

Every machine can be customized using our Machine Configurator.

Configure Now

TURNING MACHINES

VERTIMASTER VT

Vertical Turning Machine with 2 Axes (X, Z)

The VERTIMASTER VT by SCHIESS is a high-performance vertical turning machine with two axes, specifically engineered for precision machining of large, heavy workpieces. As part of the newest generation of vertical turning machines, it combines exceptional stability with flexible modularity – making it ideal for industrial applications in mechanical and plant engineering, particularly in the energy and heavy industries.

| VT | Unit | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Diameter Faceplate, max. | mm | 2.000 | 3.000 | 4.000 | 5.000 | 6.000 | 7.000 | 8.000 | 9.000 | 10.000 |

| Processing Height*, max. | mm | 3.000 | 3.000 | 5.000 | 7.000 | |||||

| Travel Distance X-/Y-Axis | mm | application-specific | ||||||||

| Faceplate Load, max. | t | 400 | ||||||||

All the above technical parameters can be customized; special dimensions on request.

Every machine can be customized using our Machine Configurator.

Configure NowTurning / Milling Machines

VERTIMASTER VM

Vertical Turning Machine with 3 Axes (X, Y, C) and Integrated Drilling/Milling Drive

The Vertimaster VM is a state-of-the-art vertical turning/milling centre that has been specially designed for machining large and heavy workpieces. With its modular design and the integration of several machining processes in a single set-up, it offers maximum flexibility and efficiency for demanding production tasks.

| VM | Unit | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Diameter Faceplate, max. | mm | 2.000 | 3.000 | 4.000 | 5.000 | 6.000 | 7.000 | 8.000 | 9.000 | 10.000 |

| Processing Height*, max. | mm | 3.000 | 3.000 | 5.000 | 7.000 | |||||

| Travel Distance X-/Y-Axis | mm | application-specific | ||||||||

| Faceplate Load, max. | t | 400 | ||||||||

All the above parameters can be customized; special dimensions on request.

Every machine can be customized using our Machine Configurator.

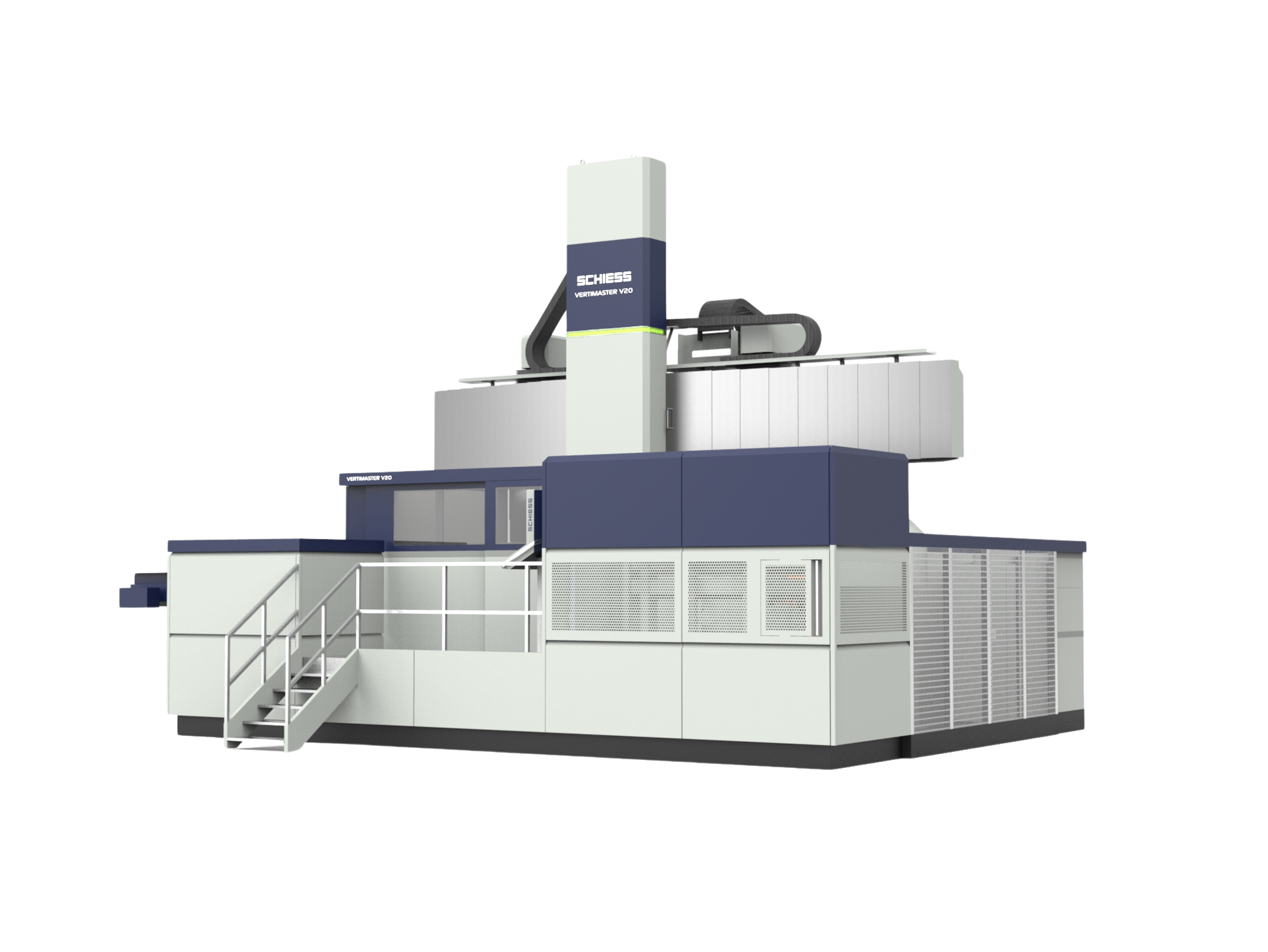

Configure NowVERTIMASTER V-SERIES

The VERTIMASTER V powerfully combines the machining processes of turning, drilling and milling in a single set-up, thus saving time and ensuring precise, effective machining of workpieces up to a diameter of 3 metres and a weight of 20 tonnes. In combination with an automatic head and tool change, the VERTIMASTER V can be quickly adapted to different production requirements.

| Specification | Unit | Symbol | V20t / V20m / V20y | V25t / V25m / V25y |

|---|---|---|---|---|

| Diameter Faceplate | mm | d | 2.000 | 2.500 |

| Machining Diameter | mm | d | 2.500 | 3.000 |

| Workpiece Height max. | mm | h | 2.000 / 2.500 | 2.000 / 2.500 |

| Passage Width (Version with Y-Axis) | mm | b | 2.700 | 3.200 |

| Workpiece Weight max. | kg | 16.000 | 20.000 | |

| Faceplate Speed (SI) | rpm | 250 | 200 | |

| Faceplate Torque (SI) (1 Drive / 2 Drives) |

Nm | 26.500 / 53.000 | 31.000 / 62.000 | |

| Travel Distance W-Axis (3 m / min) | mm | 1.200 / 1.700 | 1.200 / 1.700 | |

| Travel Distance X-Axis (20 m / min) | mm | - 1.300 / + 1.750 ... 2.550 | - 850 / + 2.000 ... 2.750 | |

| Travel Distance Y-Axis (20 m / min) | mm | ± 1.000 | ± 1.250 | |

| Travel Distance Z-Axis (20 m / min) | mm | 1.400 / 1.600 | 1.400 / 1.600 | |

| Drlling- and milling-drive, 46 kW; 3.500 rpm; 1.200 Nm: Standard for V20y / V25y, Option for V20m / V25m | ||||

Every machine can be customized using our Machine Configurator.

Configure Now